High Quality 50L Reactors For Chemical Laboratories

For over 90 years, H.S. Martin has been at the forefront of designing and manufacturing innovative scientific glassware and engineered systems. Our passion lies in understanding our customers’ requirements and delivering premium tailored solutions that exceed their expectations. In line with our commitment to excellence, we proudly present our extensive range of 50L reactors, designed to meet the diverse needs of modern laboratories and industrial processes.

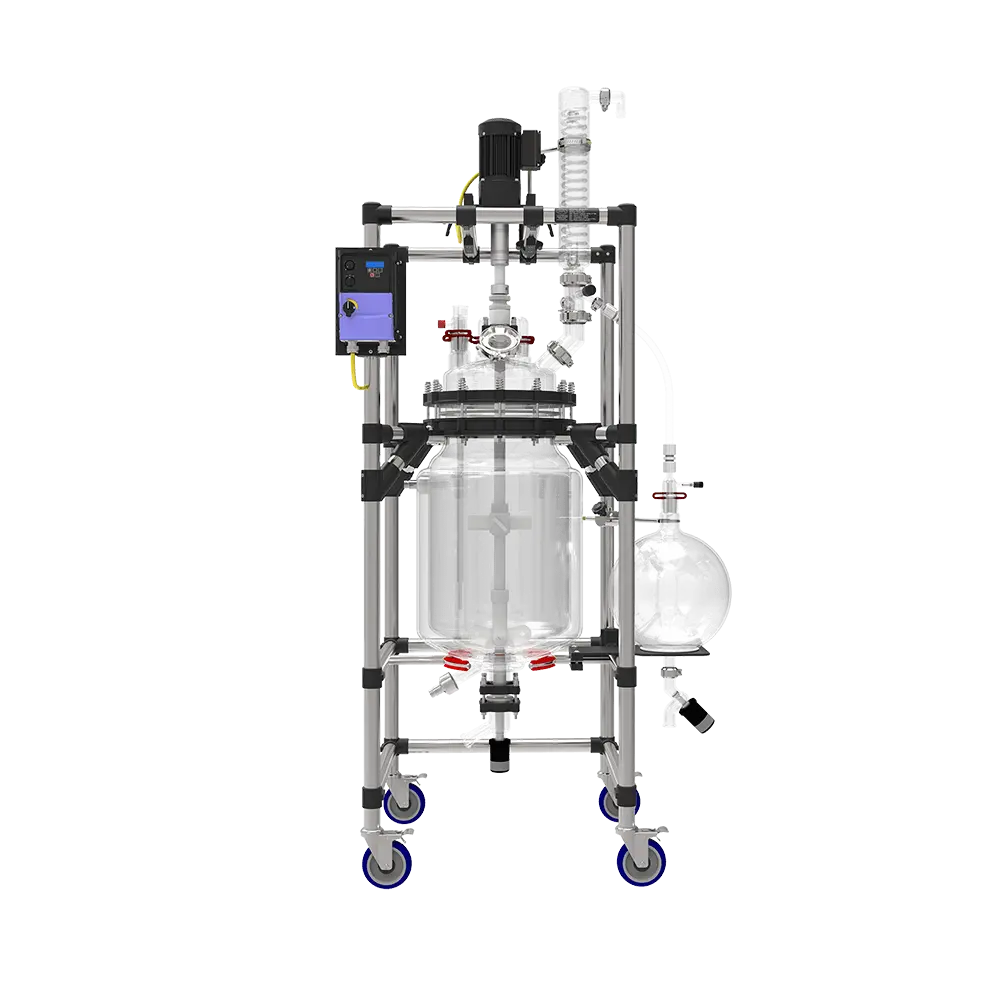

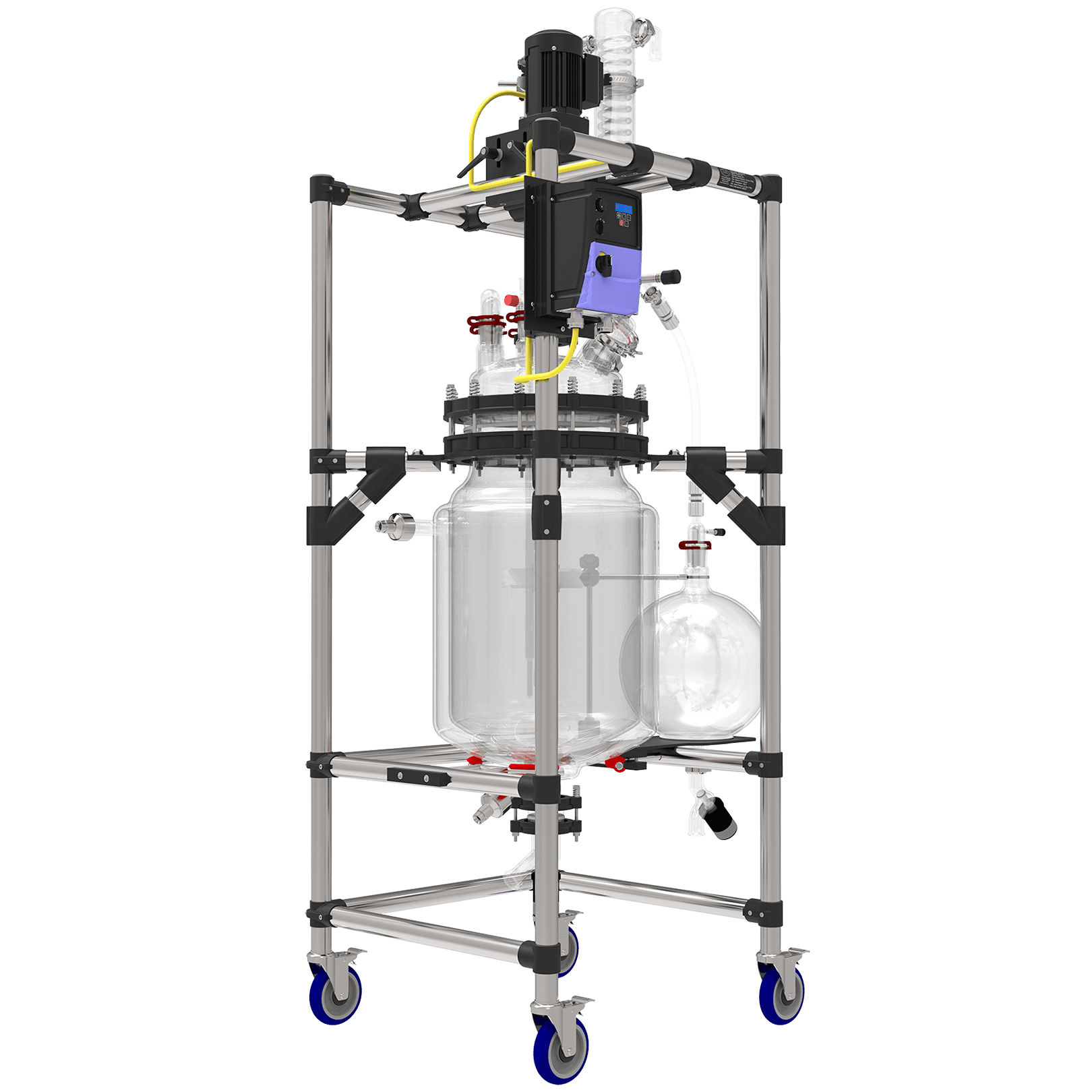

Explore the H.S. Martin Reactor System

Click on the blue circles to view more detail about the individual components featured in a standard H.S. Martin Reactor System.

Motor :

Multiple stirring motor options available. Standard 120/240V with VFD are suitable for most environments; Explosion-proof electric motors equipped with local and remote operating stations are available for hazardous environments; pneumatic gearmotors controlled with precision-flow valves are also available for facilities running air systems.

Framework : Stainless steel frame with epoxy-coated components. Provides years of durable, corrosion-resistant service. Frames are constructed to be rugged and long-lasting.

Cover : Customizable ports on the cover. Our standard cover configurations provide ample access for the most commonly used accessories. In the unlikely case that you require an access port or accessory port that isn’t provided as standard, a custom cover can be made to suit your specific requirements.

Reactor : Easy to read reactor volumes. Jacketed reactors have bold graduations on the front and rear for clear, easy to read volume reference.

Receiver Flask : Tailor your system to suit your unique requirements with receiver flasks of different sizes for longer unattended operation, or even multiple receivers to allow for continuous operation without having to interrupt the process.

Caster : Mobile frames are equipped with stainless steel-framed swivel casters that feature dual-action brakes that lock both the wheel and the swivel function for added stability. The non-marring wheels will not mark up your laboratory floor when relocating your reactor system.

H.S. Martin Reactor Systems Product Description

All standard H.S. Martin reactor systems are designed and manufactured with the following specifications.

Pressure

Up to 7 PSI (.5 Bar) to full vacuum

Temperatures

Up to +200 °C

Framework

Polished SS pipe

Material

33 expansion borosilicate glass

Wetted surfaces

Borosilicate glass or PTFE

Stirring power

AC electric, XP & non-XP, or air (pneumatic)

Stirrer bearings

16mm and 1-3/16”

Cover Port Configuration

As per specifications Other options are available

Explore our range of reactors: the H.S. Martin 50L reactor

Our 50L reactors stand out for their exceptional quality and performance. Manufactured with precision, our reactor is a testament to our dedication to providing cutting-edge solutions for scientific and industrial applications.

Our jacketed glass reactors are meticulously engineered to provide optimal control over temperature and reaction conditions. Our reactors ensure durability and reliability, even in demanding environments. The jacketed design facilitates controlled temperature operations, making them ideal for a wide range of processes, from simple synthesis to complex chemical reactions.

What are 50L reactors used for?

50L reactors play a pivotal role in numerous laboratory and industrial processes. These versatile glass reactors are used in a variety of applications, including:

- Synthesis of organic compounds

- Pharmaceutical research and production

- Petrochemical processing

- Polymerization reactions

- Material synthesis and characterization

- Environmental testing

- Food and beverage production

- Specialty chemical

Types of 50L reactors:

Our 50L reactors includes various configurations to suit a multitude of requirements. Whether you need a reactor for vacuum or atmospheric environments, or specialized processes, we have the perfect solution for you. Some common types of 50L reactors in our lineup include:

- Jacketed glass reactors with flange ports for easy customization

- Vacuum jacketed glass reactors for precise control over reaction conditions

- Process reactors with built-in condensers for efficient solvent recovery

- Reactors with controlled temperature systems for precise thermal management

- Air-reactive materials reactors with inert atmosphere capabilities for handling sensitive compounds

Features of 50L reactors:

Our 50L reactors are equipped with a range of features designed to enhance efficiency, safety, and usability. Key features include:

- Robust reactor vessels constructed from high-quality borosilicate glass for superior chemical resistance

- Outer jackets for efficient temperature control and insulation

- Flange ports for easy installation of accessories and auxiliary equipment

- Ball joint connections for secure assembly and leak-free operation

- Rotating parts with variable speed control for precise agitation and mixing

- Integrated condensers for efficient cooling and solvent recovery

- Safety features such as overpressure protection and temperature monitoring for operator peace of mind

Looking for the right 50L glass reactor for your needs?

Choosing the right reactor for your specific requirements is essential for achieving optimal results and ensuring safety. Our team of experts is here to assist you every step of the way. Whether you need advice on selecting the appropriate reactor configuration or require customized solutions tailored to your application, we’re here to help.

With our commitment to customer satisfaction, ensuring prompt delivery of your glass reaction equipment. Additionally, our comprehensive after-sales support ensures that you receive assistance whenever you need it.

Our 50L reactors offer unmatched performance, versatility, and safety. Whether you’re conducting synthetic reactions in the laboratory or scaling up production in an industrial setting, our reactors are the perfect choice for your needs. Contact us today to explore our wide range of products and experience the H.S. Martin difference.